Introduction to the Titanium Laser Device In today’s rapidly evolving technological landscape, laser devices are at the forefront of various applications, ranging from medical treatments to industrial manufacturing. One of the most innovative materials used in these advanced devices is titanium, a metal known for its strength, durability, and biocompatibility. Titanium laser devices have emerged as a game-changer in many industries, providing unparalleled precision, efficiency, and versatility. This article delves into the significance of titanium laser devices, their applications, and how they are revolutionizing different fields.

What is a Titanium Laser Device?

A titanium laser device is a tool that uses titanium as an integral part of its construction, often in the form of a laser-cutting or laser-engraving tool. Titanium, being highly resistant to corrosion and capable of withstanding extreme conditions, is often utilized in the laser’s components, such as the housing, focusing lenses, and other critical parts. Titanium’s lightweight nature and high strength-to-weight ratio make it an ideal material for precision devices that require both durability and portability.

The laser itself typically uses various types of beam technology, such as fiber lasers or diode lasers, to generate focused light energy. This energy is then directed towards a material or surface for cutting, engraving, or other specific applications.

Applications of Titanium Laser Devices

1. Medical and Surgical Procedures

One of the most significant advantages of titanium laser devices is their ability to perform precise and minimally invasive medical procedures. In surgeries, titanium lasers are often used for cutting or coagulating tissue. Titanium’s biocompatibility ensures that it does not react adversely with human tissues, making it ideal for use in delicate surgeries, such as ophthalmic procedures, dental surgeries, and cosmetic enhancements.

Titanium lasers are also utilized in skin treatments. Their precision allows for targeted therapies like laser resurfacing, which helps in reducing wrinkles, acne scars, and other skin imperfections without causing significant damage to surrounding tissues.

2. Industrial Applications

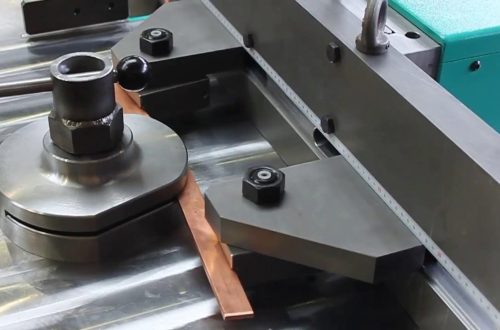

In the manufacturing sector, titanium laser devices are crucial for cutting and engraving metal materials. The robustness of titanium ensures that the laser equipment can endure high levels of heat and pressure, making it perfect for use in heavy industries such as automotive, aerospace, and electronics.

Titanium laser devices offer precise cuts on tough materials like steel, aluminum, and, of course, titanium itself. They are often used for creating intricate designs, structural components, and even components used in medical implants.

3. Precision Engineering

Titanium is widely recognized for its strength and resistance to wear and tear. These properties make it ideal for applications requiring precision engineering. Titanium laser devices are used in creating highly detailed parts for various mechanical systems, from aerospace components to high-performance machinery. The ability to achieve micrometer-level precision means that titanium laser technology plays a key role in ensuring product quality and functionality.

4. Art and Design

Titanium laser devices are also being embraced by artists and designers who want to experiment with the combination of light and metal. The laser’s precision allows for intricate designs on titanium surfaces, which can be used in the creation of jewelry, sculptures, and other artistic pieces. These devices can engrave detailed patterns, logos, and images onto titanium without damaging the material itself.

5. Laser Welding

Laser welding, a technique used to join two pieces of metal together, benefits immensely from the durability and precision of titanium laser devices. In industries such as aerospace, automotive, and medical device manufacturing, where high strength and minimal distortion are critical, titanium lasers are frequently employed to achieve clean, strong welds.

Benefits of Titanium Laser Devices

- Durability and Longevity: Titanium’s natural resistance to corrosion ensures that devices using this material are built to last, even under harsh conditions.

- Precision: Titanium laser devices are renowned for their ability to produce fine, precise cuts and engravings. This level of accuracy is essential in fields like surgery, manufacturing, and design.

- Lightweight: Despite being incredibly strong, titanium is a lightweight material, which makes these laser devices portable and easy to handle.

- Biocompatibility: For medical applications, titanium’s ability to integrate seamlessly with biological tissues without causing adverse reactions makes it ideal for surgical procedures and medical device manufacturing.

- Efficiency: Titanium lasers require less energy for operation, making them more energy-efficient than traditional metal-cutting or engraving methods.

Future of Titanium Laser Devices

As laser technology continues to advance, the potential applications of titanium laser devices are expanding. With improvements in laser power, precision, and energy efficiency, these devices will play an even more crucial role in fields like robotics, nanotechnology, and even space exploration. Moreover, as industries demand more sustainable and eco-friendly practices, titanium laser devices are expected to meet these needs with lower emissions and less waste.